While Volvo plant equipment is predominantly geared towards the construction and materials handling industries, Volvo loaders have proved quite popular with Irish farmers and contractors.

Both powerful and reliable, Volvo loaders command a high second-hand resale value, but that is only one half of the story of their Irish popularity.

In the 70’s and 80’s, Volvo LM ‘all-rounder’ loaders particularly found favour as handlers for the sugar beet industry.

Also, in the 1980’s, the Clarke Michigan 35B was another popular choice for pushing up silage. Purchased by Volvo BM, the Clarke Michigan 35B and Volvo’s LM loaders put down roots of confidence and paved the way for Volvo’s L series of articulated loaders, first released in 1986.

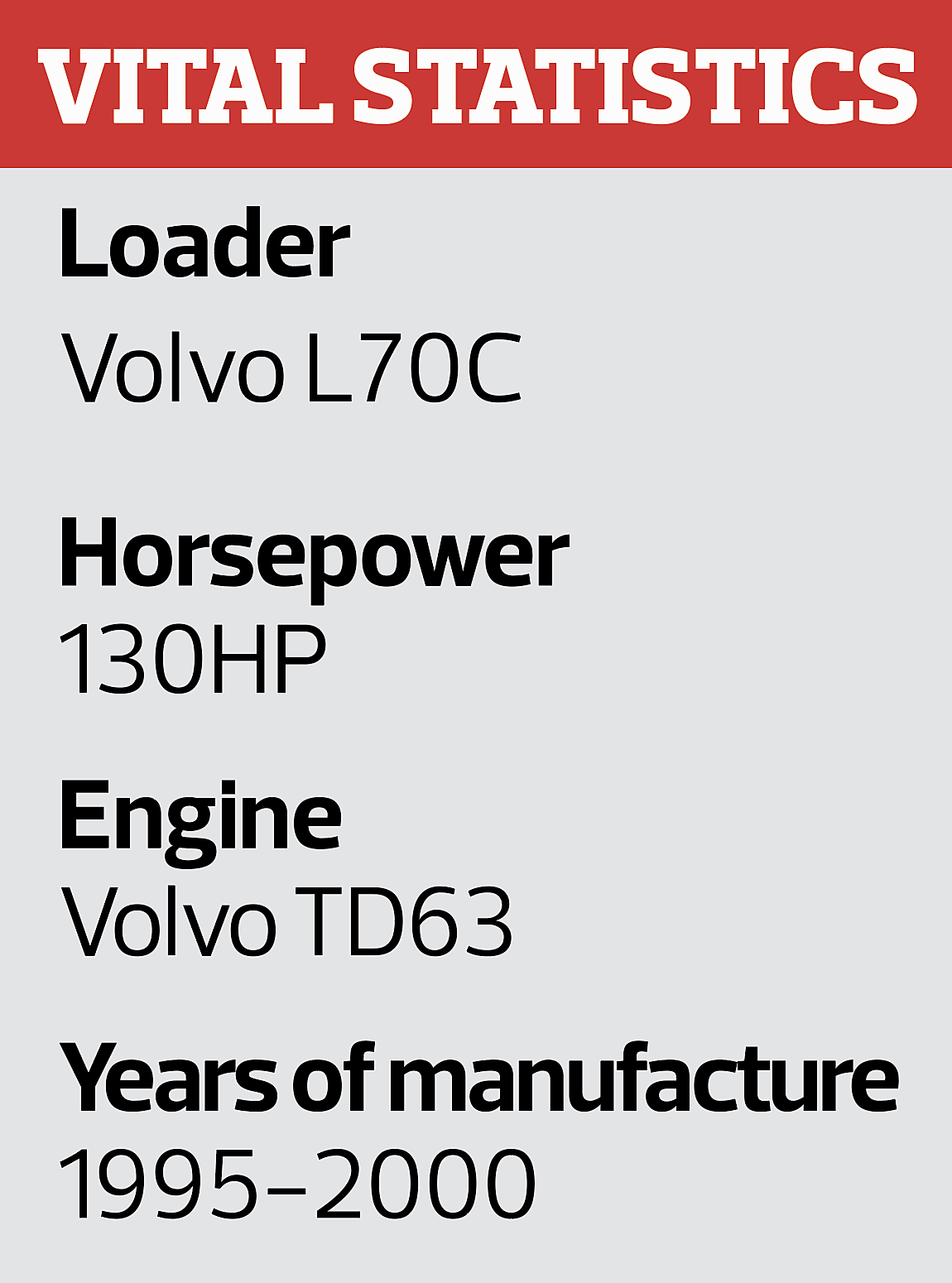

With the ‘L’ representing loader and the number designating the turning lifting weight in tons, the Volvo BM L70 and L90 were common sight.

A feat of marketing and branding genius, Volvo upgrades all its construction equipment simultaneously, designated by a letter.

In 1995, the L range of loaders was upgraded from the B series to the C series, along with Volvo’s entire construction portfolio.

Powered by Volvo’s 6 cylinder 5.5l TD63 engine, the L70C is rated at a substantial 130hp.

More impressively, the TD61 engine produces its maximum torque at a lowly 1100rpm, a characteristic of Volvo loaders continued to this day.

Weighing in at 10.5 tons, the L70C was an ideal machine for pushing up silage and was a popular choice amongst larger operators.

The loader is equipped with Volvo’s new APS II transmission with 4F/3R power shift torque convertor transmission, complete with an automatic function–APS.

The L70C is fitted with the ‘Care Cab’, designed around the operator.

The cab boasts a large expanse of tinted glass with a curved windscreen, larger door, and narrow pillars to maximise visibility.

Most importantly the C series of loaders saw Volvo move from the parallel lift arm loader unit of previous loaders, to a TP - Torque Parallel - which has continued to this day.

In typical Volvo fashion, the loader is controlled by 3 lever ‘lollipop’ type controls– while many other manufacturers use a joystick– and a hydraulic output of 160l/min.

Interestingly, the C series were the very last loaders to have the Volvo BM name applied. Although a nod to Volvo’s heritage, the ‘BM’ was completely dropped across the entire Volvo range in 1997, making C type loaders with the ‘BM’ branding somewhat unique.

Contact Peter at [email protected] or see Instagram @flashphotoscork.